This would interrupt the main loop each time the selected pin will change its state from low to high, high to low or both. So, in order to not interfere and create timing issues, we should use interruptions, in this case pin state interruptions. At the same time that we read the receiver PWM values, we have to read the IMU data and calculate the PID values and also write a signal for each of the 4 ESCs.

#Arduino pwm write code

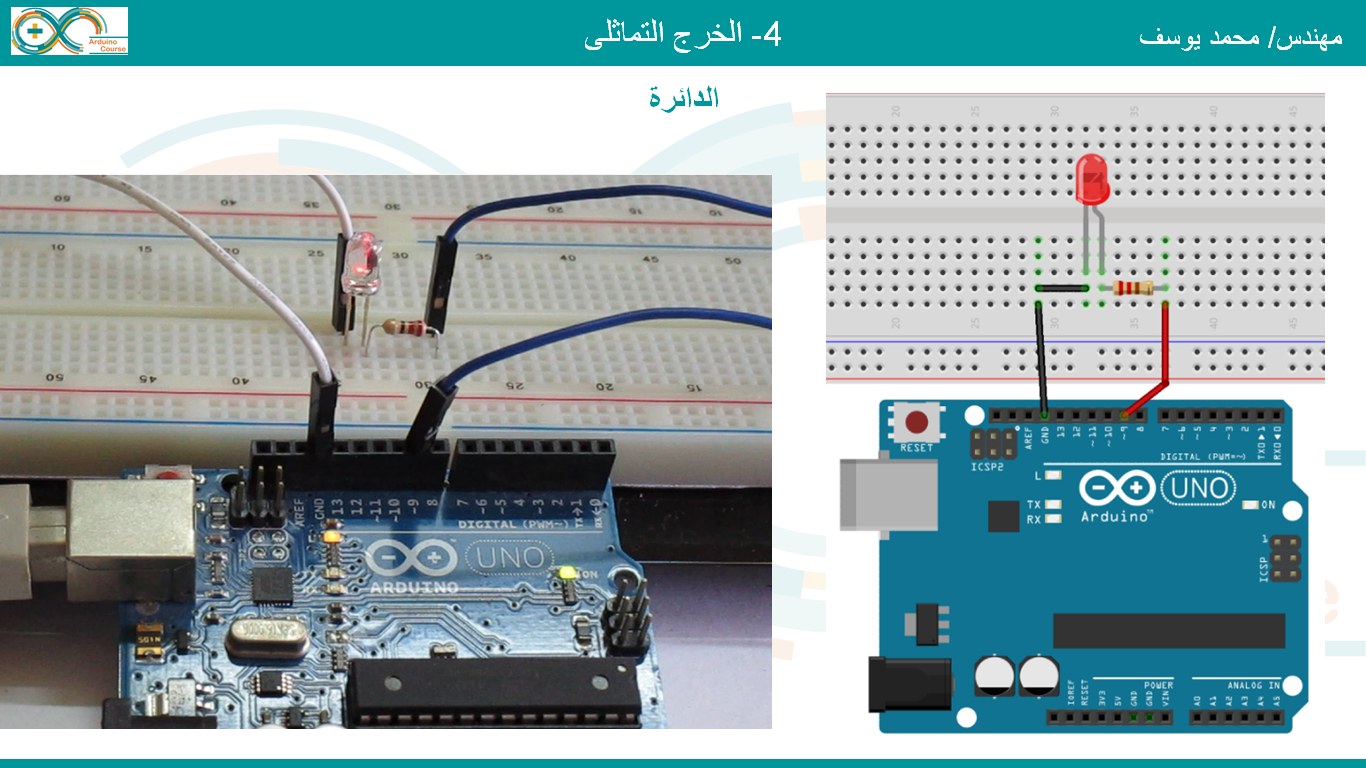

But that is not the best solution because in the flight controller code the main issue is timing. We could use the pulse in function to measure the pulse width. The code will work the same in case of the Arduino NANO. Well first of all let’s share ground and 5V with the receiver and connect channel 1 to pin 8 of the Arduino UNO for the test. So, we have to connect this signal to the Arduino and read the 1000 to 2000 value. In this case we have 67Hz which is a commune value. The frequency is usually in a range from 40 up to 200 hertz. The pulse width of radio controllers usually go from 1000 to 2000us as we can see here. I’ve powered the receiver applying 5V to it, turn on the transmitter and connected one signal to the oscilloscope as we can see below. First of all, let’s take a look on how the PWM signal that the receiver gives us looks. This causes the TIMER n ISR to be called 255 times for each PWM cycle.In this part we will work with this last 4 pins.

#Arduino pwm write software

In this software implementation of 8-bit PWM, the TIMER n frequency is set for 255 times the target PWM frequency (eg, 200Hz becomes 200*255=51kHz). The method for sharing this interrupt amongst class instances was described in this previous post. So, to retain flexibility, the a #define USE_TIMER at the top of the library header file is used to select which hardware timer is used (1 or 2).Īs TIMER n is a global resource, each object instance of the class must be driven from the same TIMER n interrupt. In the Arduino libraries, TIMER0 is used by the Arduino millis() clock, TIMER1 is commonly used by the Servo library and TIMER2 by the Tone library. The library should work on other Arduino boards (eg, MEGA) with slight modifications, but using it for non-AVR architectures would need extensive rework. It uses either TIMER1 or TIMER2 to implement an interrupt driven clock off which the PWM signal is generated. This library implementation is for AVR processors (specifically Atmel328P processors found on Uno and Nano boards). The limit is a practical solution to the problem of excessive resource being devoted to processing interrupts and is defined as a constant value in the library, easily changed if needed. The MD_PWM library implements user defined frequency PWM output for any digital pin software, limited to 300Hz. However, at low PWM frequencies, this should be a manageable issue. The downside of the software option is that the CPU is used to monitor the time signal and create the PWM digital output, taking processing time away from other tasks. Another is to create a software solution to toggle any output pin at the desired PWM frequency and duty cycle. One solution is to change processor hardware to one with more PWM pins.

It would be really useful to have PWM available on more I/O pins. In this case we don’t have enough hardware PWM pins to get the job done (see this previous post about Motor Controllers). Sometimes this is not enough.Īs an example, for two DC motors with a PWM controller, 4 PWM signals are required. So, if an application requires two external interrupts (pins 2 and 3) and an SPI interface (pins 10, 11, 12, 13), there are really only three remaining PWM-capable pins available for additional control. However some of these pins also have very useful alternate functions: Pin The Arduino Uno and Nano use the same processor and have six hardware PWM pins (3, 5, 6, 9, 10, 11).

For 8-bit PWM common on AVR microcontrollers, the duty cycle is controlled by a number between 0 and 255 (0% and 100%). Most microcontrollers have PWM generation hardware built into the processor’s output pins. The longer the signal is ‘on’ compared ‘off’, the higher the total power that can be supplied to the load. A 50% duty cycle is what is commonly called a ‘square’ wave. The duty cycle of a PWM signal is the proportion of ‘on’ time to signal’s total time, given as a percentage. The average voltage and current available to the load are controlled by turning the signal on and off at a fast rate (square wave). Pulse width modulation (PWM) is a method of reducing the average power delivered by an electrical digital signal by chopping it up into discrete parts.

0 kommentar(er)

0 kommentar(er)